Enabling a safer working environment with digital solutions

In Boliden’s converter area, full production runs side by side of extensive maintenance work. Daily, maintenance personnel work close to the converter furnaces, while large overhead cranes mounted in the ceiling transport molten material in ladles to and from the converter furnaces. The risk of work-related incidents is obvious and ensuring safety requires good coordination, good communication, and good understanding of each other’s tasks.

The collaboration between Mobilaris Industrial Solutions and Boliden Rönnskär was initiated to mitigate the risk of accidents in the converter area, by making overhead crane operators aware of where people and different working groups are located, while a lot of activities are happening at the same time. In the cabins, the operators get an overview of the area and see the positions of people below, shown as small icons on a screen. If anyone gets close to the overhead crane’s working area, the operator receives an instant warning. Also, if people and maintenance personnel on the floor are approaching a moving crane, they are warned through a flashing light signal in the helmet.

“For me, the advantage of the digital solution is that our overhead crane drivers get a better overview of how many people there are in the converter area and where they are located, which is otherwise very difficult for them to see. We have now used this solution for some time, and I think it works well. Once you have mounted the indicators on the helmets, it is very easy to handle. We will implement this solution for our contractors so that they also understand the importance and the simplicity of using it.”, says Maria Westerberg, Unit Manager Converter at Boliden.

“The digital solution is an additional tool for our overhead crane drivers and different working groups to be able to safely follow rules and routines. For example, for a mechanic welding in front of a converter, a light signal alert in the helmet makes it possible to move away of danger when the overhead crane is on its way while the overhead crane driver can continue his task in safe way”, continues Carola Grönberg, Section Manager Converter/Anode at Boliden.

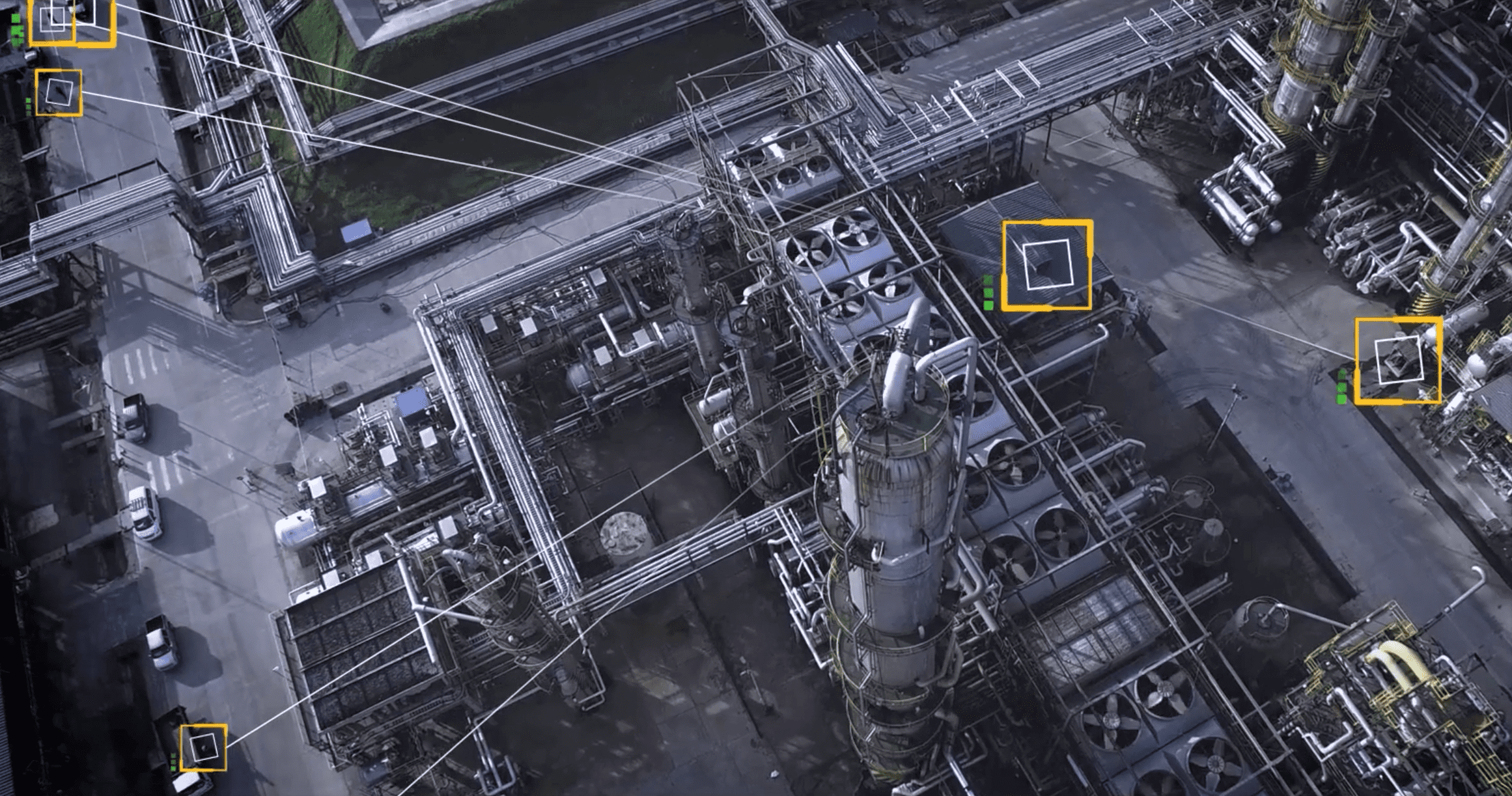

The Mobilaris Prevent™ solution

The digital solution that has been implemented is based on an UWB (Ultra-Wideband) technology, guaranteeing a reliable system with high speed and precision accuracy. Combined with Mobilaris Situational Awareness, people will not only be warned in case of potential danger, but operators will have visual support to get an overview of the area, see where people are located and easier foresee what will happen. To get started, personnel is equipped with personal tags identifying their precise location in real-time. Geofences are thereafter set up around overhead cranes to detect breaches, which triggers the warning signal to workers and crane-vehicle operators.

Successful implementation of new technology

At Boliden Rönnskär, automation and digitization are strategic focus areas. Marcus Brännström, Section Manager Automation and Digitalization at Boliden, has been responsible to manage the digitalization project. The goal of the project was to create benefits for overhead crane operators and other employees in the converter area, the place where most people work side by side of maintenance of the converters. By involving different users early in the project, Marcus received a lot of valuable feedback from the user perspective, that was used for further development and to successfully reach the goals of the project.

“For us, it was good to start with a pilot project to try out the new technology and get the end users feedback in an early stage. Today, there is modern technology available to support safety. Knowing where people are is often key to avoid dangerous situations.”, says Marcus Brännström.

For the overhead crane operators and others in the converter area, the feeling of keeping up with production in a safe way has been improved.

“We think the digital solution is great. We don’t notice it very much in our everyday work, but if a serious situation arises, then it’s there. We’re working in an environment that require that we deliver our job on time. This means a time pressure towards production while at the same time looking after each other and coordinating maintenance work with production. The safety has been improved for everyone. We have a greater possibility to foresee what will happen and where others are located. It allows both overhead crane drivers and workers on the floor to do their job in a safe way”, says Joakim Lundqvist, Process Operator Converter.

The Boliden Rönnskär site in Skellefteå, north of Sweden